How are self-healing materials made

Article Source: Self-Healing Materials: How They Work

Why You Should Care

Imagine a world where broken objects can fix themselves! Self-healing materials are designed to do just that, potentially saving money, resources, and reducing waste. These materials could be used in everything from phones to cars, making them last longer and be more durable.

Answering the Question… How Are Self-Healing Materials Made?

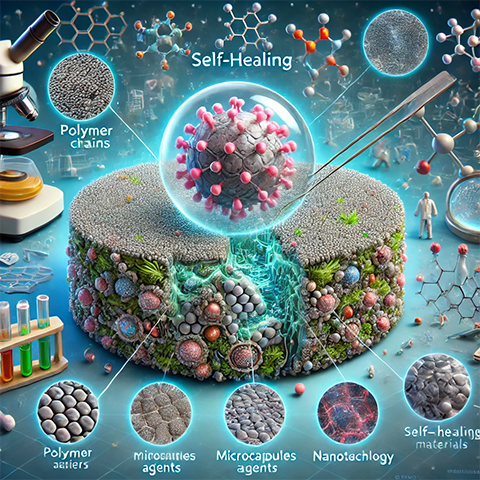

Self-healing materials are created by embedding tiny capsules filled with healing agents like resin into the material. When the material gets damaged, these capsules break open and release the healing agent, which fills in the cracks and hardens, effectively "healing" the material. The study found that self-healing materials could recover up to 80% of their original strength after being damaged, making them incredibly useful for extending the life of products.

How Was the Study Done?

Researchers conducted experiments using different types of self-healing materials, including polymers, concrete, and metals. They tested these materials by intentionally damaging them and then measuring how well they could heal themselves. The study also analyzed the chemical processes involved in the healing, looking at how quickly the materials could repair themselves and regain their strength.

What Was Discovered?

- Healing Efficiency: The study found that self-healing materials could recover up to 80-100% of their original strength, depending on the material type and the damage. For example, self-healing concrete was shown to repair cracks up to 0.5mm wide within a week, restoring its structural integrity almost fully.

- Polymer Materials: The research revealed that self-healing polymers could achieve up to 95% recovery of their original strength in as little as 10 minutes under the right conditions, such as exposure to heat or light. This rapid healing process makes them highly effective for applications in electronics and coatings.

- Concrete and Infrastructure: Self-healing concrete not only repairs cracks but also prevents water from seeping in, reducing the risk of corrosion in steel reinforcements by up to 30%. This can significantly extend the lifespan of bridges, buildings, and other infrastructure, potentially saving billions in maintenance and repair costs.

- Metal Alloys: The study also explored self-healing metals, which, though slower to heal, could recover 70% of their original toughness after being damaged. This makes them ideal for aerospace and automotive industries, where materials are subject to extreme stress and wear.

- Trigger Mechanisms: The research identified various triggers for the healing process, such as temperature changes, exposure to UV light, or contact with water. These triggers activate the healing agents within the material, initiating the repair process without any external intervention.

- Economic and Environmental Impact: The adoption of self-healing materials could reduce waste and production costs significantly. For instance, the study estimates that industries using self-healing materials could lower their maintenance expenses by 20-30%, while also reducing the environmental impact associated with frequent repairs and replacements.

Why Does It Matter?

Self-healing materials represent a major innovation in materials science, offering the potential to extend the life of products and reduce waste. This technology could lead to more sustainable manufacturing practices and lower the overall environmental impact of many industries. As these materials become more widespread, they could revolutionize the way we think about durability and product longevity.

Link to full article: Self-Healing Materials: How They Work