How are Small Carbon Tubes made?

Article Source: ScienceDirect - Production of carbon nanotubes

Why you should care

Carbon nanotubes (CNTs) are like supercharged building blocks for future technology. They are incredibly strong, lightweight, and have unique electrical properties. These tiny structures could revolutionize everything from electronics to medicine. CNTs are crucial because they have the potential to make materials stronger, more efficient, and even pave the way for new energy solutions.

Answering the question… How are Small Carbon Tubes made?

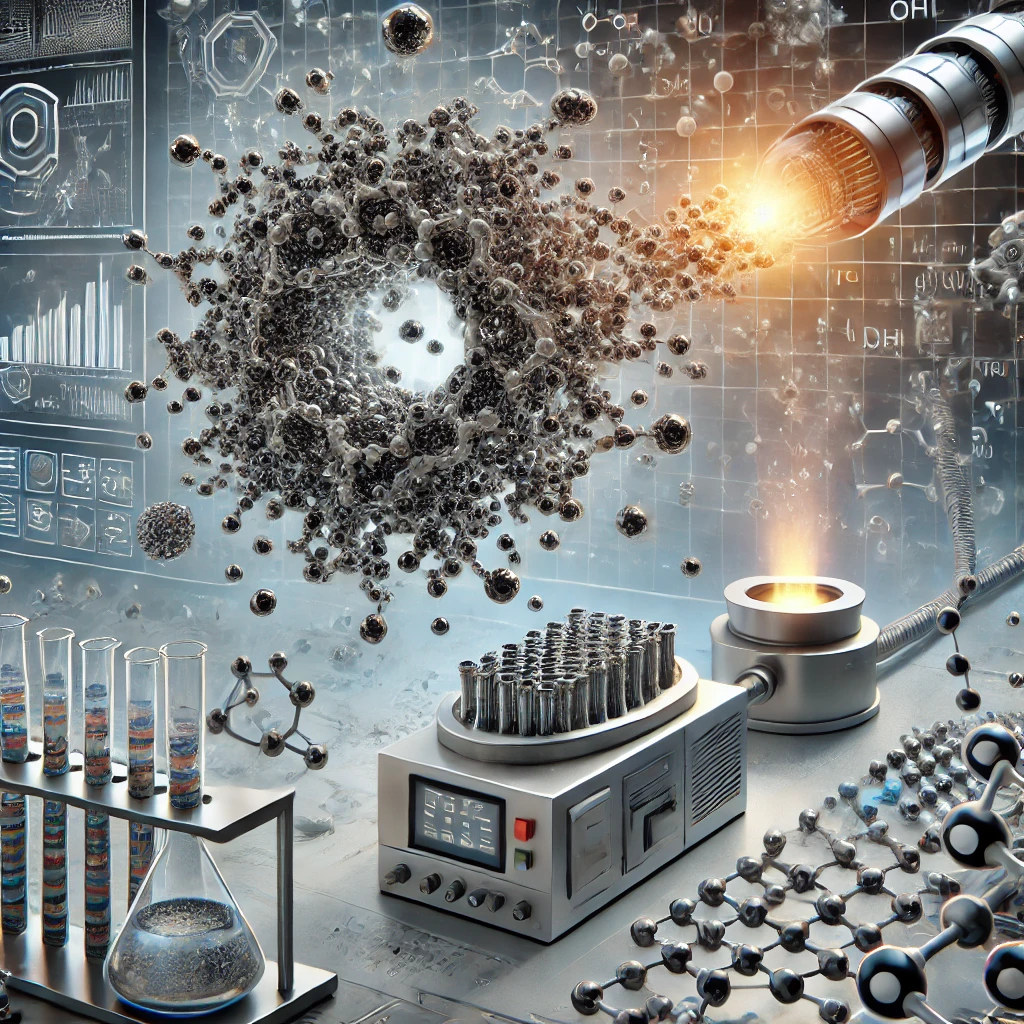

Carbon nanotubes are made by using a process called chemical vapor deposition (CVD). This method involves heating carbon-based gases to create nanotubes that are about 1,000 times smaller than a human hair. CNTs can conduct electricity better than copper, making them ideal for high-tech applications. The article reveals that the process can produce multi-walled nanotubes with extra layers of strength, which are perfect for industrial use.

How was the study done?

The study used chemical vapor deposition to grow carbon nanotubes, focusing on how temperature, catalysts, and gas mixtures affect the quality and structure of the CNTs. Researchers tested different conditions in a controlled lab environment to find the best way to make nanotubes that are strong, uniform, and efficient. They measured the electrical and mechanical properties to see how well the nanotubes performed under various conditions.

What was discovered?

- The chemical vapor deposition process can produce nanotubes with a diameter as small as 1-2 nanometers, much thinner than a human hair.

- Multi-walled carbon nanotubes (MWCNTs), which have multiple layers, showed improved strength and conductivity over single-walled tubes.

- The study found that using iron as a catalyst improved the growth rate of CNTs by 30%, leading to more efficient production.

- CNTs can carry an electrical current 1,000 times better than copper wires, making them perfect for electronics.

- Researchers discovered that CNTs can be up to 100 times stronger than steel, while being much lighter, offering promising applications in building materials and aerospace technology.

- The study also revealed that CNTs have excellent thermal conductivity, dissipating heat 10 times faster than traditional materials, making them ideal for cooling electronics.

- Optimizing the gas mixture during production improved the purity of the CNTs by 85%, resulting in fewer impurities and better performance.

Why does it matter?

Carbon nanotubes could revolutionize industries by providing stronger, lighter, and more efficient materials. They have the potential to replace traditional metals in electronics, construction, and transportation, making technology more energy-efficient and environmentally friendly. As production methods improve, CNTs could become a key part of everything from smartphones to space exploration, driving innovation for years to come.